BEKO AC 540 HP 350 High Pressure Heatless Desiccant Dryer

Beko Technologies DRYPOINT® XC AC 540 HP 350 High Pressure Heatless Desiccant Air Dryer, 1/2 in Inlet Connection

Beko Technologies DRYPOINT® XC AC 540 HP 350 High Pressure Heatless Desiccant Air Dryer, 1/2 in Inlet Connection AC 540 HP 350- Brand Name: Beko Technologies

- Part Number: AC 540 HP 350

- Check Stock

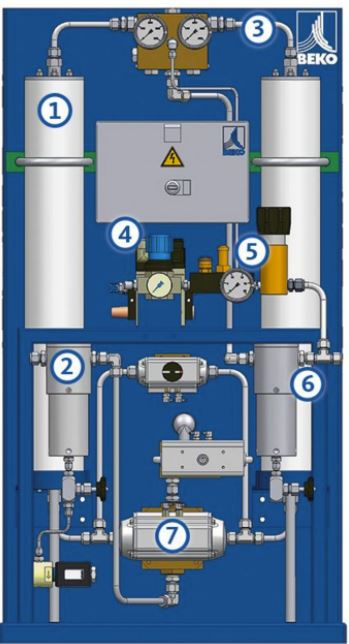

Regenerative desiccant dryers are frequently found in industrial applications around the world. These dryers use a desiccant material, which adsorbs the water vapor in the air stream. Heatless desiccant dryers utilize a small amount of dried air to regenerate the desiccant in one tower while the other tower dries the compressed air. DRYPOINT® XC Series heatless desiccant dryers provide very low dew points, are designed around reducing energy and process waste and provide a very user friendly interface.

Beko Technologies DRYPOINT® XC High Pressure Heatless Desiccant Air Dryer, 1/2 in Inlet Connection, 40 to 130 deg F Inlet Air Temperature, Air Flow Rate: 260 scfm, 350 bar Air Pressure,-40 deg F Dew Point Temperature, 5 to 50 deg C Maximum Temperature, Stainless Steel Housing, 66 in Overall Height, 31 in Overall Width, 18 in Overall Depth

| Air Flow Rate | : | 260 scfm |

| Air Pressure | : | 350 bar |

| Dew Point Temperature | : | -40 deg F |

| Housing Material | : | Stainless Steel |

| Inlet Air Temperature | : | 40 to 130 deg F |

| Inlet Connection Size | : | 1/2 in |

| Maximum Temperature | : | 5 to 50 deg C |

| Overall Depth | : | 18 in |

| Overall Height | : | 66 in |

| Overall Width | : | 31 in |

- High quality components are used in construction and combined with high level engineering

- Reduces traditional height by up to 30%

- Each dryer includes a feature rich controller with energy saving modes

- Open frame design where all features are front-mounted, simplifies maintenance and reduces costs

- The DRYPOINT® AC HP is equipped with a number of individual valve units

- Their separate fixtures ensure that there is no extra load on the pipes and also protect the dryer against vibration

- This enhances the operational safety of the dryer and reduces maintenance and spare parts costs

- Pressurized components are made in stainless steel as standard

- Highly efficient adsorbents guarantee that the pressure dew point is kept below the required level

- Two separate pressure reducers for control and regeneration air respectively ensure reliable operation at all times

- The low pressure section is protected by a safety valve

- The control and regeneration air is drawn off behind the after filter, ensuring extra reliability and accurate control

- Thanks to the compact design, the dryer fits into virtually any plant

Add To Favorites List

Add To Favorites List